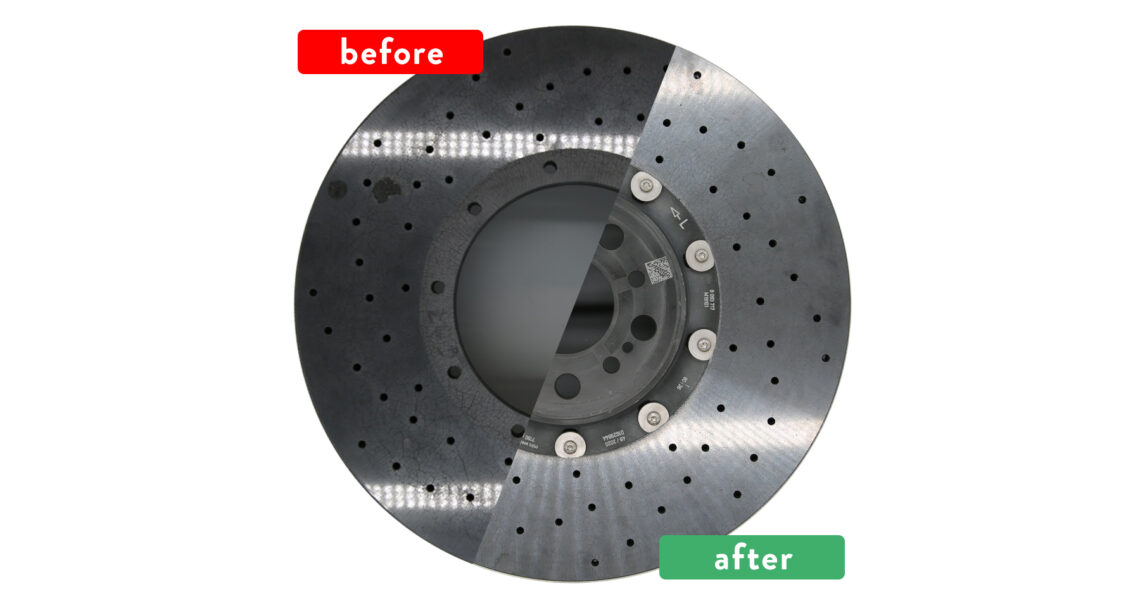

Rebrake GmbH has developed a process in early 2023 that allows to recondition a worn carbon-ceramic brake disc by renewing the friction layer. Now, damages of all types can also be sustainably repaired.

These damages can be mechanical, such as those caused by carelessness during tire changes or handling in the repair shop. But they can also involve a phenomenon known as delamination or detachment of the friction layer, which can occur suddenly during normal use. The cause of this is a failure of the bond between the supporting body and the friction layer.

The repair is done by specifically applying the carbon/silicon carbide-containing material to the damaged area after it has been thermally and mechanically cleaned. In a high-temperature step in a vacuum atmosphere, a reactive bond is formed between the friction layer and the supporting body through the addition of silicon. The damaged area contains a friction layer made of similar material with comparable composition and hardness to the original friction layer. After restoring the surface condition through a precise fine grinding that meets the manufacturer’s tolerances, the brake disc can be used safely and permanently again.

Extensive tests have shown that brake discs repaired in this manner are once again durable and equally resilient as undamaged discs.

The advantage for customers and repair shops is that from now on, damaged brake discs, which often cost over €6.000, do not need to be fully replaced but can be repaired cost-effectively. This is a significant benefit, especially for used cars or for repair shops where even minor damages can lead to high costs.

Rebrake Ceramic Service GmbH, Bayreuth, September 25, 2024