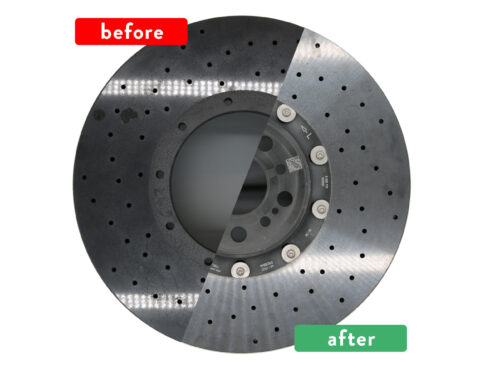

Rebrake GmbH has developed a process in early 2023 that allows to recondition a worn carbon-ceramic brake disc by renewing the friction layer. Now, damages of all types can also be sustainably repaired. These damages can be mechanical, such as those caused by carelessness during tire changes or handling in the repair shop. But they…

Modern sports cars and high-performance vehicles with a sporty focus are increasingly being equipped with carbon-ceramic brake systems at the factory. The advantages of these brake systems are their lower weight and better braking performance. However, they are also more expensive than conventional steel brake systems. If they need to be replaced due to damage…

Starting January 2023, REBRAKE will operate a new factory located in Bayreuth/Bavaria. The new facility means a quicker turnaround, getting you, our valued customer, back on the road quicker and with better discs.

On November 14, 2022, Rebrake GmbH applied for a European patent for the unique and innovative coating application to carbon ceramic disk brakes. Pursuit of the expensive European patent indicates Rebrake’s confidence that the cutting edge Rebrake Friction Layer process is the best option for recovering carbon ceramic disc brakes to their OEM capability quickly…

Prof. Dr. Krenkel held the Chair of Ceramic Materials at the University of Bayreuth and is considered the original “inventor” of the carbon fibre reinforced ceramic brake disc which entered automotive series production around the year 2000. Dr Krenkel is now a member of Rebrake’s Advisory Board and helps us to further develop durability and…

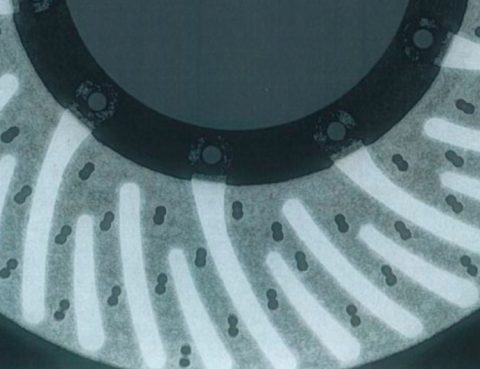

The older carbon-ceramic brake discs are, the more critically the screw connections. they must be checked regularely. Contact corrosion, material fatigue due to permanent heating processes up to 800 degrees Celsius and more cause the screw connections of the ceramic rotor and pot (usually an aluminium alloy or stainless steel) to become friable. This can…

Brake disks made from carbon ceramic can finally be perfectly restored Carbon braking systems have revolutionized motor sport as barely any other innovations have. The highly efficient functioning, the noticeable lower weight, the stable brake performance in race mode, and the extremely long lifespan make ceramic brake disks a must. The ceramic brakes heats up…

When brake disks made from carbon ceramic are worn down they can be repaired with ease Carbon ceramic brake disks are predominantly used in top class models made by Ferrari, Audi, Porsche, Mercedes or Lamborghini. Experts think that the highly efficient ceramic brakes will also win over the mid-range market, bit by bit. The advantages…

The service life of carbon ceramic brake discs is enormous, renewed discs should last over 100,000km Motorsport fans, environmental politicians and activists and even ordinary motorists actually agree on this point: carbon ceramic brake discs are the future. Particulate matter is the subject of city centres. Ceramic brake discs in our vehicles could effectively counteract…

High-performance and environmentally friendly: REBRAKE renewal service for ceramic brake discs of all manufacturers and diameters The company FOXX Automotive Components from Weßling near Munich has established a worldwide unique process with REBRAKE, a powerful and reliable process for the renewal of ceramic brake discs. Brake discs of all sizes and manufacturers, even older brake…