The remanufacturing process in detail

Step 1

Step 2

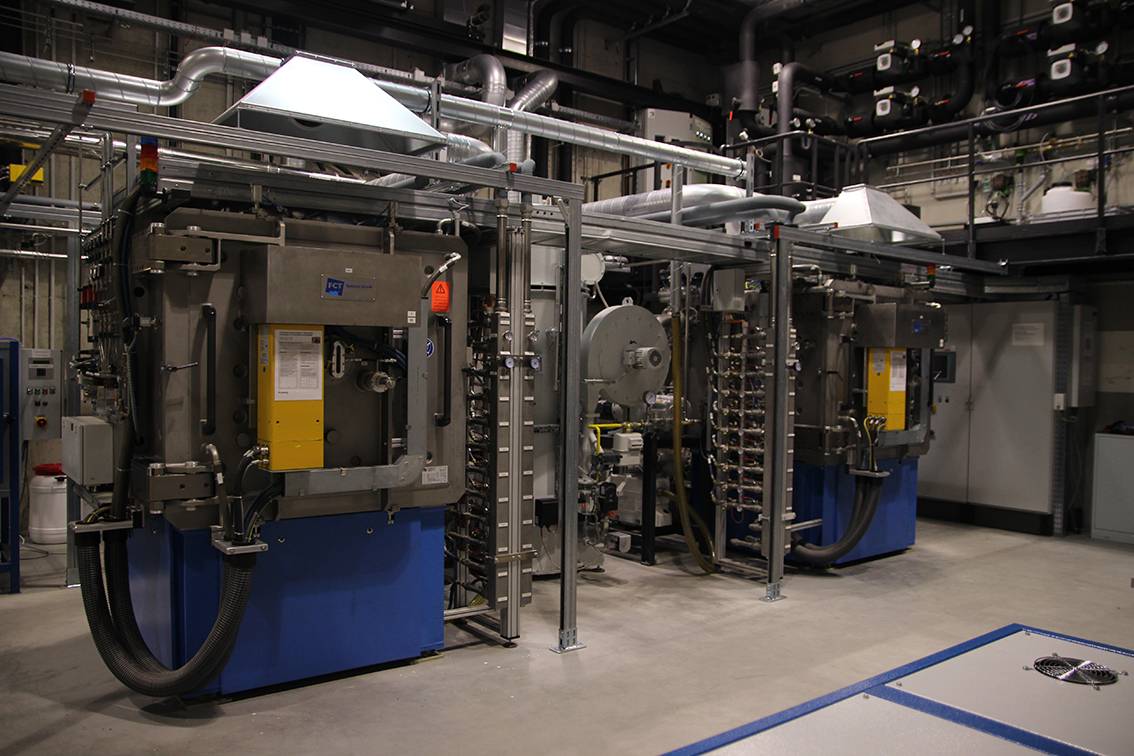

Afterwards, the disc surface is cleaned using a high-pressure blasting process with corundum to remove brake pad residues and impurities. In the second step, another thermal cleaning at high temperature is carried out to remove any impurities from the material and to prepare the surface for coating.

Afterwards, the disc surface is cleaned using a high-pressure blasting process with corundum to remove brake pad residues and impurities. In the second step, another thermal cleaning at high temperature is carried out to remove any impurities from the material and to prepare the surface for coating.Step 3

Area specific repairs and full-surface reconditioning of the worn brake rotors are accomplished during the reconditioning phase with high-tech process. A new friction layer has a high SiC content and is extremely wear-resistant. The friction layer is made of the combination of liquid silicification and high-temperature oven. This process is what bonds the friction layer and the brake rotor support structure ensuring excellent adhesion. In addition, the process much faster than in the past, so you get your reconditioned brakes back quickly – in most cases, within 15 business days.

Step 4

Grinding and polishing of the surface is conducted to an accuracy of 1/100 mm. The rotor is checked again, weighed, and balanced for final delivery.

The brake rotor now has a new friction layer, is back to the original dimension in terms of thickness and diameter and has the target weight specified by the manufacturer.